Blow-in insulation is the process of blowing insulation material into attics, walls or around crevices. When installing in attics of commercial building, fiberglass, cellulose, and dense insulation may be used. Blown-In may be applied to metal buildings, warehouses or office buildings. It has a texture like down feathers and is able to fit into tight spaces like walls or between wires or ducts.

Metal buildings require different amounts of heat transfer due to the size of the space. Since there are more people going in and out of the building, this will require a different amount or type of insulation.

In commercial projects, blow-in is constructed from various substances, including recycled cardboard, recycled newspaper glass, and other ordinary trash. technicians use special equipment to blow out the material.

Like Foam and Batt, Blow-in provides excellent insulation for commercial properties. They can be applied to:

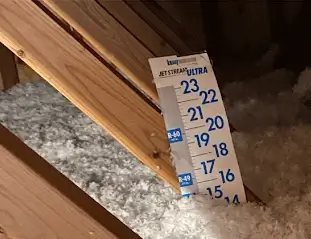

R-value is determined by a grading system used to check the Insulation’s effectiveness. The higher the R-Value, the more insulated the material is. Depending on the location of the blow-in insulation, it could require a different layer of material.

Below are the two R values for Blow-in Fiberglass and Cellulose:

R values can be affected by climate, type of material and section of building. floors, Walls, and attics will all use different values.

Don’t let decreased energy efficiency, uneven airflow, and low air quality effect the comfort of your business! Request a commercial insulation estimate today and get your project started with Insulation First!